Research Update: Reduce Waste and Increase Sustainability in the Postharvest Process

Research Update, powered by FloraLife

Terril A. Nell – Professor Emeritus, University of Florida

Success in baking and bartending depends on using the right ingredients in the right proportions. Otherwise, the fallen cake or undrinkable cocktail goes into the trash, as well as all the labor, time and resources that went into making these. The flower world is really no different. Success depends on choosing the right product and mixing it to the right proportions to avoid waste. As the floral industry focuses on sustainability, reducing waste becomes a critical issue.

Waste costs money and has a negative impact on the environment. Waste does not simply boil down to flowers. There are many other things that we need to include into the waste equation such as water, energy, post-harvest products, packaging, fuel, etc. Attention to every aspect of postproduction ensures a positive consumer experience and pays dividends for growers, wholesalers and retailers. Measuring and mixing hydration and flower food solutions, anti-ethylene treatments and even cleaning products as directed will produce the best results.

1 – Even the best varieties need hydration and nutrition.

Production techniques and flower variety will influence the postharvest performance of cut flowers, but even the best varieties need hydration and flower food solutions tailored to flower type, distribution stage and shipping time. Many flowers should also be treated with anti-ethylene products or anti-leaf yellowing solutions. Figure 1 illustrates ethylene damage in roses. Ethylene damage on roses can result from ethylene production within the flower or from external sources. Rose ethylene sensitivity has not been widely acknowledged in the industry even though the first report of sensitivity was over 30 years ago. All treatments–hydration, anti-ethylene, and anti-leaf yellowing–are important to the longevity and quality of flowers received by retailers and enjoyed by consumers.

2 – Choose the right product and use it correctly.

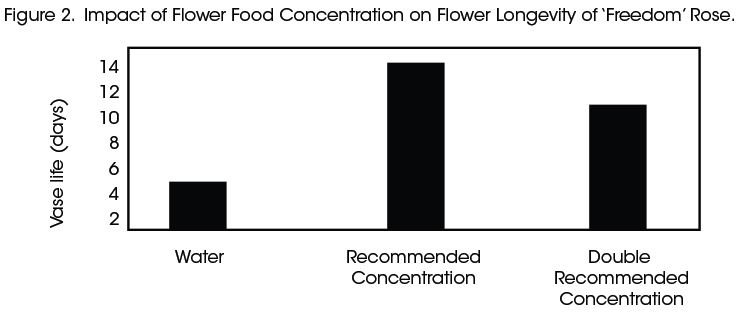

Hydration and flower food solutions are designed to accelerate water flow up stems and to provide supplemental sugar to flowers. At the University of Florida, we found that these solutions were very effective when used properly by growers, wholesalers, retailers, and consumers. For example, using properly-mixed FloraLife Crystal Clear® at the recommended concentration increased vase life of ‘Freedom Rose’ by 9 days compared to water with no additives. Doubling the concentration of the flower food did not produce better results. (Figure 2). In other words, there was a clear benefit from properly-mixed flower food, but stronger solutions did not lead to better results. Similar results were observed with other rose varieties and other flowers.

From a sustainability perspective, flower foods are wasted when used at higher-than-recommended amount. New flower food formulations can be reused for more than a week, making it possible to use these products more efficiently.

3 – The need for properly-mixed solutions continues at the retail level.

Flowers in bouquets, bunches and floral arrangements continue to benefit from flower foods. Keeping stems in properly-mixed solutions is an insurance policy against loss. Delivering well-hydrated flowers will avoid premature wilting due to lack of water in containers and/or floral foam.

4 – Help consumers understand the importance of hydration with properly-mixed solutions.

Many bouquets now include packets of flower food, but few consumers measure water to make a proper solution, and many throw the packets out with the cellophane and rubber bands used on bouquets. Educate your customers regarding the importance of feeding flowers and instruct them on proper use. An educated consumer is a repeat purchaser.

Other processes to reduce waste and drive sustainability:

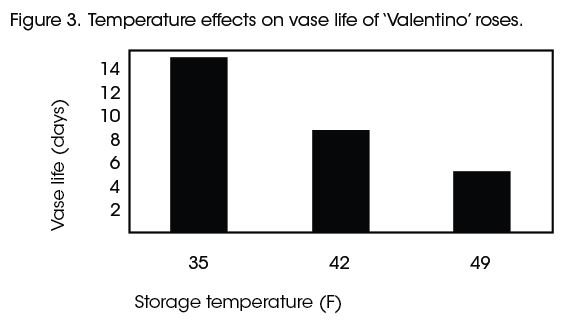

5 – Respect the cold chain.

Pay attention to optimal storage temperatures at all times. Flowers should be delivered in temperature-controlled vehicles to avoid overheating.

6 – Use recycled paper, cardboard, and plastics.

Consumers value environmental responsibility, and research has shown that they are willing to pay more for papers, cardboard, and plastic containers made from recycled materials. Sort trash according to local ordinances and recycle as much as possible.

7 – Dispose of Flower and Plant Debris Properly.

Removing flower debris from coolers, processing centers and design areas is important to reduce the spread of disease and to reduce the possibility of ethylene production by dead and decaying plant/flower materials. Dispose of these materials responsibly.

8 – Keep work areas clean.

Sanitation is important in reducing the spread of disease and insects. Disease spores are so small that we can only see them with a microscope. The only sure way to prevent spread is to keep all surfaces clean, including vases, buckets and cutting tools. Fortunately, there are products like FloraLife® D.C.D.® that have a residual effect against diseases when used in recommended concentrations.

A lot of time and expense goes into producing floral products. Each stem or plant represents an investment of space, material, water, energy, packaging, fuel and manpower. The goal is to make that investment translate to a positive consumer experience and profitability. As we look at ways to make our industry more sustainable, reducing waste is critical. Good care and handling practices involve using flower foods, hydration solutions, ethylene treatments, cleaning product as well as good care and handling habits are important tools to minimize waste, but only if chosen and mixed properly.

Product availability depends upon geographical region. To find out more about FloraLife® postharvest products or the availability in your region, contact your local FloraLife representative or email [email protected].