Avoiding Ethylene Injury on Potted Plants

Research Update, powered by FloraLife

Terril A. Nell, Ph.D., AAF – Professor Emeritus, University of Florida

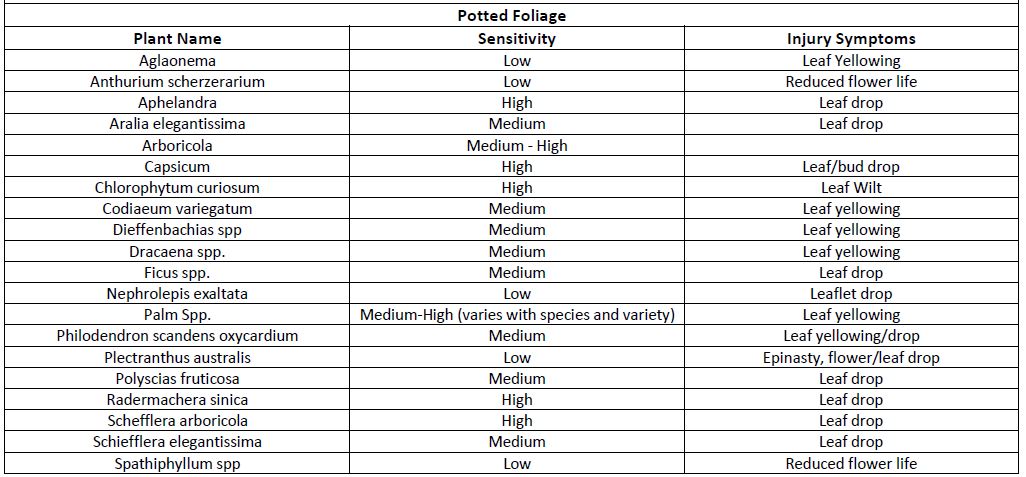

Ethylene reduces plant performance and marketability of many potted plants. The damaging effects of ethylene have been recognized on flowering potted plants for a long time, but the effects on potted foliage plants were not broadly identified until the last decade or so. Potted foliage growers have stopped selling supermarkets and big box stores some plants that exhibit leaf edge burn or leaf drop. Research has shown these plants to be ethylene-sensitive. As a result, some beautiful and unique foliage plants are not available to consumers. Ethylene-sensitive plants can be treated effectively to prevent ethylene- related damage and loss of marketability.

What is Ethylene?

Ethylene is a colorless, odorless naturally-occurring hormone that is not detectable without scientific testing equipment. This hormone is effective at very low concentrations. Plants may be injured due to ethylene in the air emitted by dying and decaying fruits, vegetables and flowers, combustible engines, and fruit-ripening rooms such as those used to treat bananas.

Flowers themselves can produce ethylene when stressed due to lack of water, high temperatures, or extended storage. Vibration can also trigger internal ethylene production that leads to injury symptoms. This explains why some plants exhibit injury symptoms even if they have not been exposed to ethylene gas in the environment. Anti-ethylene treatments prevent the action of external ethylene and the production of internal ethylene, even if the flowers are stressed.

What injury does Ethylene cause?

Ethylene injury symptoms are similar regardless of the source of ethylene (external gas or internal production). The injury symptoms are very diverse and depend on the plant species. Ethylene may cause buds, flowers, and leaves to drop or wilt prematurely, marginal leaf burn or drooping and a reduction of postharvest life. The reaction time following ethylene exposure varies with the plant material, temperature, and plant age.

Ethylene is more damaging at warmer temperatures and for plants that have been stored or marketed at a mature stage. Some symptoms may appear in 1 – 2 days while other symptoms may take longer to become evident. For instance, hibiscus plants may not show any symptoms until 3 – 4 days after being removed from the shipping box at which time all buds and flowers are likely to turn yellow and drop. Kalanchoes may show symptoms within 24 hours of exposure to ethylene. Some foliage plants exhibit marginal leaf burn that resembles drying out after 6 – 8 days. Potted roses placed in low light display areas will develop yellowing buds in 3 – 4 days due to light stress. All these symptoms can be prevented by treatment with anti-ethylene products prior to shipping. And, yet many of ethylene-sensitive plants are not receiving special postharvest treatments to prevent ethylene injury.

Growers Can Treat Plants Prior to Shipping and Storage to Prevent Ethylene Damage

Potted plants may be treated with 1-MCP (EthylBloc™) to prevent ethylene injury. A small sachet of EthylBloc™ can be placed in a shipping box or an EthylBloc™ “Truck Kit” can be used to treat an entire truck. Both application techniques are equally effective.

EthylBloc™ is a powder that is activated by moisture. The resulting gas prevents the damaging effects of external ethylene and the production of internal ethylene. Moisture in the box activates the sachets. Water is added to a container of EthylBloc™ powder just before the shipping truck door is closed. FloraLife provides information on the amount of EthylBloc™ for different size trucks.

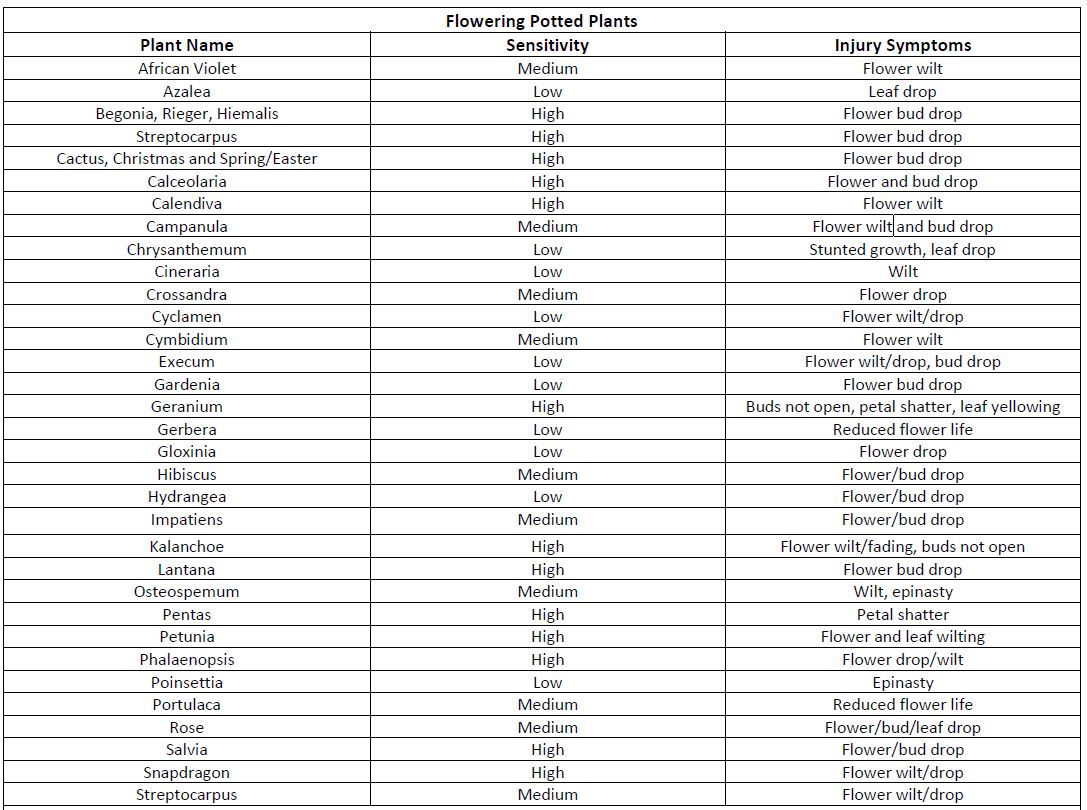

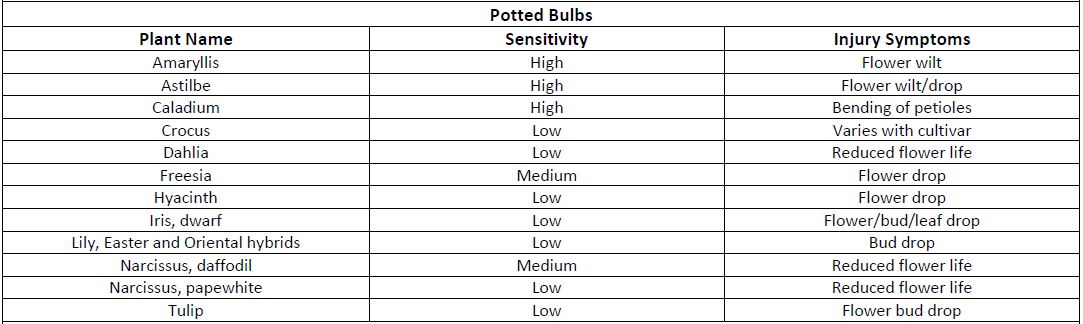

The following tables provide details about the severity of ethylene damage for potted plants and the sensitivity of each plant to ethylene. Ethylene sensitivity may vary with variety.

To find out more about EthylBloc™ or the availability in your region, contact your local FloraLife representative or email [email protected].

*Product availability depends upon geographical region.